DPSS (Diode-Pumped Solid State) lasers, whether YVO4 or green, set the standard for precision, versatility, and efficiency. Combining energy performance and adaptability, these technologies are proving to be indispensable in sectors such as electronics and many other industrial segments. Let's delve into the world of DPSS lasers, highlighting their characteristics, applications, advantages, and benefits.

What is a DPSS laser?

The DPSS laser is a key solid-state technology in laser marking. It uses a laser diode to pump a solid-state crystal, such as YAG (Yttrium Aluminum Garnet) or YVO4 (Yttrium Vanadate), and generate a precise, high-quality beam.

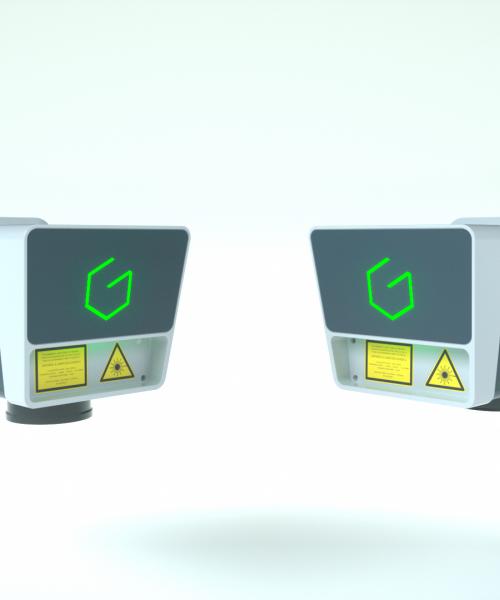

DPSS Laser

Operation characteristics

The DPSS laser is based on optical pumping. A laser diode emits light that is absorbed by a doped crystal, such as YAG or YVO4, thus exciting its atoms. These release energy in the form of photons, which are amplified in a resonant cavity to produce a coherent beam.

The standard 1,064 nm laser emission can be converted to different wavelengths as required: green light (532 nm, second harmonic generation) or ultraviolet (355 nm, third harmonic generation). This flexibility makes it possible to engrave various materials with high resolution.

DPSS technology guarantees coherent, stable beams, even for applications requiring extreme precision. Thanks to diode pumping, it combines efficiency and cost-effectiveness, making it a popular solution in the industrial sector.

DPSS Laser

Key benefits

DPSS lasers stand out for their energy efficiency, consuming less power for equivalent performance to CO2 or fibre lasers. Their pump source, based on laser diodes, enables sufficient power while keeping costs under control.

Versatile, DPSS lasers work on a wide variety of materials:

- Reflective metals (copper, gold, and silver),

- Heat-sensitive materials,

- Multilayer or sensitive materials.

Their precision and low thermal footprint prevent damage to materials and ensure optimum aesthetics.

Their robust, gas-free design makes them long-lasting and low maintenance industrial laser marking systems. This makes them ideal for even the most demanding industrial applications.

The different types of DPSS laser:

GREEN LASER 532 nm

The DPSS green laser, with a wavelength of 532 nm, produces visible light and offers optimum absorption for specific materials. Its reduced focal point makes it particularly effective for detection, alignment, and precision marking.

The DPSS green laser 532 nm is ideally suited to high-precision applications, such as marking soft plastics or heat-sensitive materials. Its ability to limit thermal transfer reduces the risk of damage to sensitive materials—in other words, cold marking.

YVO4 LASER 1064 nm

The YVO4 laser uses a neodymium-doped yttrium vanadate crystal to deliver high performance for fine engraving and complex marking.

It operates at a wavelength of 1,064 nm, enabling it to produce a highly concentrated beam invisible to the naked eye. This specificity enables it to interact and mark a wide variety of materials (metal, plastic...), while maintaining high resolution and precision, ideal for fine marking.

The main applications for Green & YVO4 Lasers

DPSS green lasers:

The main applications

Electrical equipment marking

Green lasers excel at marking plastics with specific properties used in electrical equipment, especially those with flame-retardant or heat-resistant additives.

The green laser 532 nm can be used to produce contrasting markings for traceability applications, such as CE markings, technical specifications, or pin references.

Precious metal marking

Suitable for metals such as gold, silver, copper, and stainless steel, the green laser produces contrasting, corrosion-resistant markings.

It is also appreciated for applications in jewelry and medical devices, thanks to its precision and ability to avoid heat distortion.

DPSS YVO4 lasers:

The main applications

The YVO4 laser is a versatile solution for high-precision marking and engraving applications. Its short pulse duration and high peak power make it ideal for marking metals, plastics, ceramics, and electronic components with sharp, high-contrast results.

YVO4 lasers are commonly used in industries such as electronics, medical devices, automotive, and luxury goods for applications like serial numbers, barcodes, logos, and micro-marking.

Green laser vs. YVO4 laser: Key differences

| Laser type | Laser wavelength | Suitable materials | Highlights |

| Green | 532 nm | Plastics and sensitive materials (soft plastics) Precious metals | Low thermal transfer, micro- precise micro-marking, high absorption |

| YVO4 | 1,064 nm | Metals Plastics | High peak power, extreme precision, versatility |

Focus on Gravotech's YVO4 laser

The "Hybrid Laser":

our YVO4 laser

Gravotech's Hybrid laser is a unique, versatile, flexible, and high-performance industrial laser marking system. It enables fast, precise marking on a wide range of materials (metal, plastic, glass, etc.).

Designed to be easily integrated into production lines, the hybrid laser is THE industrial laser marking systems. It is adapted to the most demanding environments since it resists dust, heat, and vibration. Its applications range from part traceability in the automotive industry to the personalisation of luxury goods and precision cutting.

Discover Gravotech DPSS laser machines

Gravotech’s industrial laser marking systems include the Hybrid Laser (YVO4), which offers high-speed industrial marking on plastics and metals, ensuring continuous operation, production automation, and flexibility across multiple surfaces.

The DPSS Green Laser is designed for reflective and sensitive materials, enabling cold marking on surfaces non-reactive to other wavelengths.

All Gravotech laser stations are available with green or YVO4 laser sources, adapting to various materials and marking needs.

The WeLase™ is a compact and versatile engraver for personalisation, jewelry, and small industrial parts, offering manual and preview modes with enhanced safety features.

The LW2 is a fully automated engraver optimised for batch marking and sensitive materials, featuring low heat transfer and programmable speed.

The LW3 is a high-capacity station for complex applications and large parts, ensuring precision and safety with integrated software.