Laser cutting, laser marking, laser engraving… The technologies and renderings of these three processes differ. What are the specifics of cutting? Find out all you need to know about how it works, the advantages, and the materials compatible with laser cutting machines.

Laser cutting: how it works, its benefits, and suitable materials

What is laser cutting?

Laser cutting is a high-precision process for cutting various materials by concentrating laser energy on a minimal area.

A beam is focused and amplified to raise the temperature of a precise material zone, causing it to melt or vaporise. This is what makes it possible to cut through the substrate.

This laser source generates the beam, stimulating photons in an enclosed space. There are various types of laser sources—CO2, DPSS, fibre, MOPA—each suited to different materials. The choice of laser source depends on the material being cut.

| Good to know |

What are the advantages of laser cutting?

The process offers several advantages, from design and execution to cost control.

First and foremost, it saves time, thanks to:

- a very high speed of execution - although this varies according to the type of material,

- low need for operator intervention during the cutting process, action is limited to positioning the part or material and operating the machine,

- limited post-cutting processing - no sanding or mechanical sealing is required after cutting.

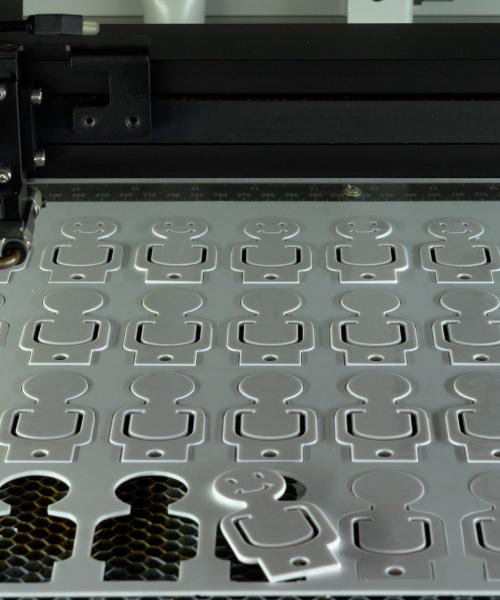

Laser cutting is characterised by high precision and versatility - enabling the creation of complex shapes on a wide range of materials. This technique opens the door to a host of applications point-of-sale advertising, signage electronic components, and small metal parts… but also making trophies, toys, models, and jewellery.

Finally, the laser cutting machine is self-contained: it requires no additional equipment or consumables (stylus, tip, blade, or other chemical product).

What materials can be laser-cut?

Depending on the source used (CO2, DPSS, fibre, MOPA…), lasers can cut a wide range of materials:

- Organic - paper, rubber, textiles, wood, leather, cardboard or cork.

- Plastics - PMMA, PA, PBT, PC, polyester, PET (except ABS and PVC).

- Metallic - aluminium, anodised aluminium, brass, copper, gold, silver, nickel, steel… thin-gauge steel.

| Reminder |

Other materials exist, specifically developed for laser engraving or cutting techniques. Examples include those listed in the Gravotech catalogue, such as Gravoply™ Laser, Gravoply™ Ultra, Gravoply™ 2, Gravotac™ Exterior, Flexilase™, or Laser Wood.

Choosing the right Gravotech's laser cutting machine

For batch cutting

The models mainly recommended for this type of use belong to the LS range, with a CO2 source. These technologies can cut different thicknesses of material.

Small CO2 laser engraver and cutter for personalisation, signage and creative.

LS100

Medium CO2 or Fiber laser engraving and cutting machine for signage and small series.

LS100 EX

Large laser engraver and cutter that can do everything.

LS900

Extra large laser engraving and cutting machine for high productivity.

LS1000XP

For single-cutting projects or large parts

For this type of project, Gravotech laser stations are the best choice. These laser cutting machines can cut metals up to 1 mm and precious metals up to 0.8 mm.